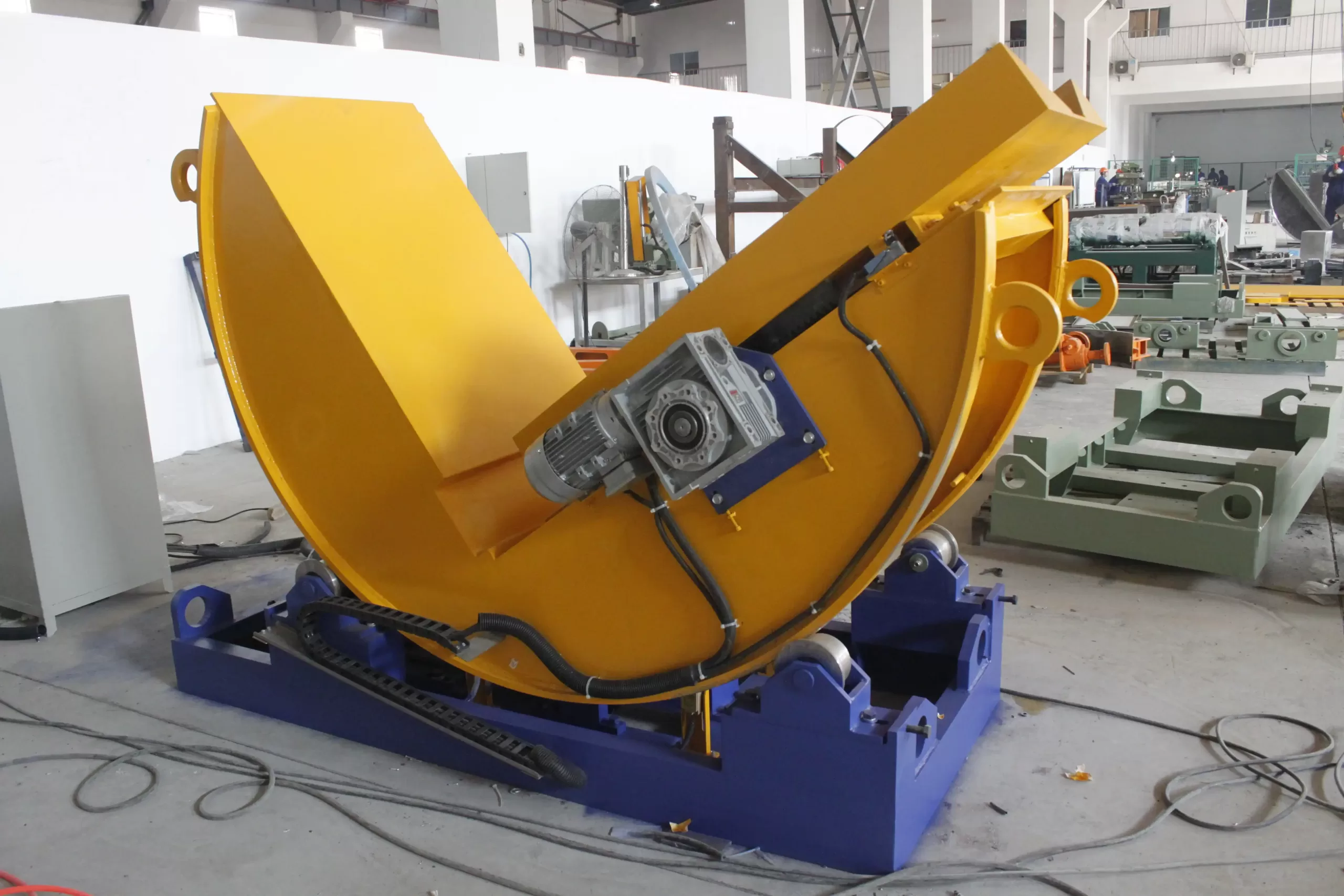

Industrial Coil Tipper

Coil tippers are a game-changer in industrial operations, revolutionizing the way heavy materials are handled in factories and warehouses. These robust machines, designed for lifting and rotating coils, enable businesses to improve efficiency and ensure worker safety. However, the decision to incorporate a coil tipper into operations often raises important questions about their value, practicality, and long-term benefits.

Efficiency and safety are at the heart of industrial innovation, and the coil tipper stands as a prime example of machinery engineered to meet these demands. It’s not just about moving coils; it’s about transforming workflows, minimizing risks, and maximizing returns. But how does it all come together?

As industries evolve, the push for streamlined operations and reduced downtime has made advanced material-handling equipment a necessity rather than a luxury. A closer look at the features, applications, and advantages of coil tippers reveals their indispensable role in modern industrial ecosystems.

[Claim: Industrial coil tippers improve efficiency and safety while offering long-term cost benefits that align with operational goals.]

Parameters:

|

Machine

|

FPCT-02

|

FPCT-05

|

FPCT-10

|

FPCT-20

|

FPCT-30

|

FPCT-50

|

Power Supply

(V/Hz)

|

Per requirement

|

Power

(Kw)

|

1.5

|

1.5

|

3.2

|

4.5

|

6.5

|

11.5

|

Max. Loading

(T)

|

2

|

5

|

10

|

20

|

30

|

50

|

Table size

(mm)

|

Per Coil size

|

Speed

(sec)

|

50-70

|

50-80

|

60-90

|

60-90

|

60-90

|

60-100

|

Machine Weight

(T)

|

2.0

|

2.5

|

3.0

|

3.5

|

4.0

|

4.5

|

Machine size

(mm)

|

Designed Per Load size

|

|

Warrantee

|

2 years

|

1. What Are the Key Features of a Coil Tipper?

1.1 Design and Mechanism

Industrial coil tippers are engineered with precision and durability. The design typically includes a reinforced steel frame, hydraulic lifting mechanisms, and safety locks to ensure smooth and secure operation. These machines are built to handle heavy loads, often exceeding several tons, with ease.

A critical feature is their rotation capability, enabling coils to be turned 90 or 180 degrees, depending on the model. This flexibility allows operators to position materials exactly as needed, reducing manual intervention and the potential for mishandling.

1.2 Performance Metrics and Specifications

Performance metrics often determine the utility of a coil tipper for specific industries. Here’s an example of typical specifications:

|

Feature

|

Specification

|

|

Load Capacity

|

Up to 30 tons

|

|

Rotation Angle

|

90° or 180°

|

|

Cycle Time

|

60–90 seconds

|

|

Energy Source

|

Hydraulic/Electric

|

|

Safety Features

|

Auto-lock, Emergency Stop

|

These machines are not one-size-fits-all; they are tailored to accommodate a variety of coil sizes and weights. Some models also feature adjustable clamps or cradles to adapt to different materials.

1.3 Safety Features

Safety is paramount in any industrial setting, and coil tippers are no exception. These machines are equipped with features like emergency stop buttons, overload sensors, and anti-slip surfaces to ensure operator safety. Additionally, the automated locking system prevents coils from shifting during rotation, minimizing risks.

1.4 Enhanced Material Handling

The integration of a coil tipper transforms material-handling workflows. Operators no longer need to rely on cumbersome manual techniques or less effective tools like forklifts. This leads to:

-

Reduced Physical Strain: Operators avoid lifting heavy loads manually.

-

Increased Speed: Faster turnaround times with automated processes.

-

Improved Accuracy: Precise placement of coils for downstream processes.

|

Key Benefits

|

Outcome

|

|

Reduced Injury Risks

|

Safer work environment

|

|

Faster Operations

|

Increased productivity

|

|

Lower Error Rates

|

Improved quality control

|

1.5 Fact Statements

True: Coil tippers significantly reduce workplace injuries caused by manual material handling.

False: All coil tippers can rotate 360 degrees, regardless of model.

2. How Does a Coil Tipper Enhance Operational Safety?

2.1 Prioritizing Worker Safety

Safety is a primary concern in industrial environments, where heavy equipment and materials create inherent risks. Coil tippers address these challenges by automating the handling of coils, significantly reducing the likelihood of accidents caused by manual lifting or improper handling techniques.

By incorporating advanced features such as automated locking systems and emergency stop mechanisms, coil tippers ensure that operators remain out of harm's way. These safety features minimize direct human interaction with heavy loads, fostering a safer workplace.

2.2 Data-Driven Insights into Safety Performance

Coil tippers have demonstrated their ability to reduce incidents in the workplace through quantifiable data. For instance:

|

Safety Metric

|

Improvement Rate After Coil Tipper Integration

|

|

Reduction in Manual Lifting Injuries

|

75%

|

|

Decrease in Material Mishandling

|

60%

|

|

Increase in Compliance with Safety Standards

|

90%

|

These figures illustrate how coil tippers not only protect workers but also help businesses align with industry safety standards.

2.3 Long-Term Safety Benefits

Beyond immediate improvements, coil tippers contribute to a culture of safety by consistently reducing high-risk activities. Over time, this leads to:

-

Lower Insurance Costs: Fewer workplace injuries result in reduced premiums.

-

Improved Worker Morale: Employees feel safer and more valued in their roles.

-

Enhanced Reputation: Businesses known for safety attract better talent and partnerships.

These benefits underline the critical role of coil tippers in creating a sustainable and safe work environment.

2.4 Conclusion

The adoption of coil tippers fundamentally changes the safety dynamics of industrial operations. By automating heavy lifting and incorporating cutting-edge safety measures, these machines mitigate risks, protect workers, and enhance overall operational efficiency.

2.5 Fact Statements

True: Automated locking mechanisms on coil tippers prevent coils from shifting during rotation.

False: Coil tippers are only suitable for lightweight materials under 5 tons.

3. What Are the Long-Term Financial Benefits of Coil Tippers?

3.1 Initial Investment vs. Operational Savings

While the upfront cost of acquiring a coil tipper can be significant, it is important to weigh this against the long-term financial benefits. The automation provided by coil tippers leads to measurable cost reductions in several areas:

|

Financial Metric

|

Average Savings Over 5 Years

|

|

Labor Costs

|

30%

|

|

Equipment Maintenance

|

25%

|

|

Workplace Injury Claims

|

50%

|

By reducing labor-intensive tasks and minimizing downtime, businesses often recoup their initial investment within two to three years.

3.2 Financial Snapshot and Efficiency Gains

Here’s how coil tippers impact cost-efficiency:

|

Area of Impact

|

Before Coil Tipper

|

After Coil Tipper

|

|

Average Handling Time

|

15 minutes

|

5 minutes

|

|

Number of Operators

|

3

|

1

|

|

Annual Maintenance Cost

|

$15,000

|

$7,500

|

These figures highlight how coil tippers optimize resources and reduce recurring expenses.

3.3 The ROI of Automation

The return on investment (ROI) of a coil tipper is not limited to financial metrics. It also includes intangible benefits like enhanced employee well-being, better compliance with safety regulations, and improved operational reliability. Companies using coil tippers report:

-

Higher Employee Productivity: Streamlined workflows allow teams to focus on value-added tasks.

-

Reduced Downtime: Reliable machinery minimizes interruptions.

-

Stronger Client Relationships: Faster turnaround times lead to greater customer satisfaction.

3.4 Dive Deeper into Cost Analysis

For an in-depth understanding, consider a case study of a manufacturing plant that integrated coil tippers into its operations:

|

Metric

|

Before Integration

|

After Integration

|

|

Annual Injury Claims

|

10

|

2

|

|

Employee Turnover Due to Injuries

|

15%

|

5%

|

|

Annual Savings

|

N/A

|

$100,000

|

This analysis demonstrates how coil tippers not only save money but also improve the overall health of the business.

3.5 Fact Statements

True: Coil tippers significantly reduce maintenance costs for businesses handling heavy materials.

False: The cost of coil tippers outweighs their long-term financial benefits.

4. How to Choose the Right Coil Tipper for Your Industry?

4.1 Key Considerations for Selection

Choosing the right coil tipper involves analyzing various factors to ensure it aligns with your operational needs. Start by evaluating the following:

-

Load Capacity: Ensure the tipper can handle the heaviest coils in your operations. Models range from 10 to 30 tons, with customizable options for specialized applications.

-

Rotation Capability: Some industries require 90° rotation, while others might benefit from 180° flexibility.

-

Energy Source: Consider hydraulic systems for high-capacity needs or electric systems for precision and energy efficiency.

Matching the tipper’s specifications to your workload is crucial for maximizing efficiency and minimizing operational disruptions.

4.2 Comparing Features Across Models

Not all coil tippers are created equal. Here’s a breakdown of how different models compare:

|

Feature

|

Basic Model

|

Advanced Model

|

Custom Model

|

|

Load Capacity

|

Up to 10 tons

|

Up to 30 tons

|

Customizable

|

|

Rotation Capability

|

90° only

|

90° and 180°

|

Adjustable

|

|

Safety Features

|

Manual locks

|

Automated locks

|

Advanced sensors

|

|

Energy Source

|

Manual hydraulic

|

Electric

|

Hybrid

|

Selecting the right model depends on the scale and complexity of your operations.

4.3 The Role of Customization

Customizing a coil tipper ensures it meets the unique demands of your industry. Industries with non-standard coil sizes or specific handling requirements benefit from tailored solutions. For instance:

-

Custom Clamps: Adaptable to irregularly shaped materials.

-

Integrated Sensors: Provide real-time feedback for enhanced safety.

-

Durable Materials: Withstand harsh environments in steel and metal processing industries.

Investing in a customized solution may involve higher upfront costs but ensures long-term compatibility with your processes.

4.4 Dive Deeper: Evaluating Manufacturer Support

The manufacturer plays a significant role in ensuring the longevity and efficiency of a coil tipper. Key factors to consider include:

-

Warranty Period: Industry standard is 1–3 years; some offer extended coverage.

-

Post-Installation Support: Maintenance packages and training for operators add value.

-

Availability of Spare Parts: Reliable supply chains prevent downtime.

|

Manufacturer Comparison

|

Warranty Period

|

Post-Installation Support

|

Spare Parts Availability

|

|

Manufacturer A

|

1 year

|

Basic

|

Limited

|

|

Manufacturer B

|

2 years

|

Comprehensive

|

Extensive

|

|

Manufacturer C

|

3 years

|

Premium

|

Guaranteed

|

Choosing a manufacturer that aligns with your business goals can significantly impact the long-term performance of the tipper.

4.5 Fact Statements

True: Customization options in coil tippers allow industries to handle unique material sizes efficiently.

False: All coil tippers come with a standard warranty period of three years.

Conclusion

Industrial coil tippers are more than just tools—they are transformative assets that streamline operations, enhance safety, and deliver significant financial benefits over time. By automating heavy-lifting tasks and minimizing risks, these machines empower businesses to meet the demands of modern industrial operations.

When choosing a coil tipper, consider the unique needs of your industry, including load capacity, safety features, and the reliability of the manufacturer. With the right machine in place, businesses can achieve improved productivity, safer workflows, and optimized long-term costs.

[Claim: The right coil tipper is an investment in safety, efficiency, and operational excellence, ensuring long-term success for industrial businesses.]