DIFFERNCE VERSION OF THE WIRE PACKING SOLUTINOS

1. VERTICAL VERSION WIRE COIL PACKING MACHINE

It is an economical and reliable steel wire coil wrapping machine designed to handle a wide range of coil sizes and materials. Equipped with an advanced PLC control system and a user-friendly touchscreen interface, operators can quickly adjust settings to accommodate various coil dimensions and wrapping materials. This machine is especially suited for efficiently packing small and lightweight wire coils.

Key Features:

-

Adjustable wrapping tension for optimal protection

-

Vertical steel wire coil packing, with manual coil loading and unloading

-

Foolproof operation that requires no complex installation

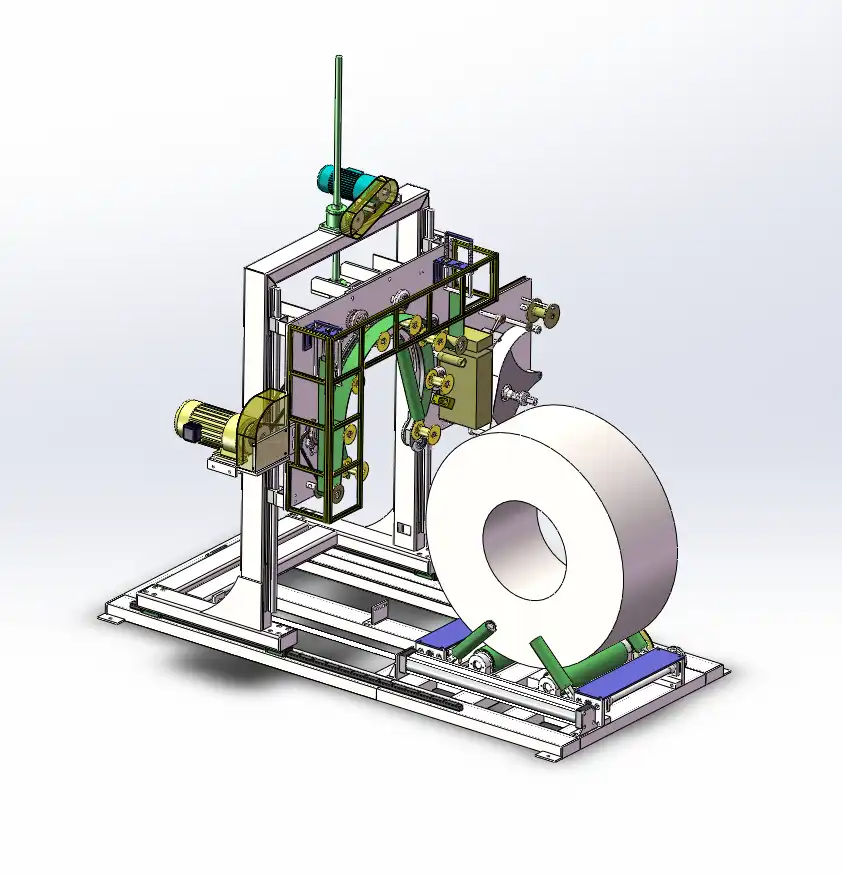

2. Horizontal Version Steel Wire Coil Packing Machine

The

solution designed to efficiently package steel wire coils with

precision and care. This innovative machine features a "coil ID to sky"

packing orientation, ensuring that soft wire coils are not deformed by

gravity during the wrapping process. Wrapping station forward and backward adjustable

Key Features:

-

Horizontal Coil Loading: “ID to sky” setup protects coil shape from gravity-induced distortion.

-

360° Support Rollers: Enable stable rotation and uniform wrapping coverage.

-

Large Coil Compatibility: Designed to handle oversized wire coils with ease.

-

Customizable Design: Adaptable to your coil size, weight, and packaging specs.

3. Big Steel Wire Coil Packing Machine with Trolley

The

Big Machine with Trolley is a robust and efficient solution for

packaging large, heavy wire coils. Its integrated trolley system

simplifies the process of moving heavy coils in and out of the wrapping

station, making it an ideal choice for crane handling applications. This

high-performance machine ensures safety and is typically suited for

wire coils with a width of 400-1000mm.

Key Features:

-

Trolley system: Facilitates easy transport of heavy wire coils to and from the wrapping station.

-

Crane-friendly: Designed for safety integration with crane handling operations.

-

Safety-focused: Engineered to prioritize operator safety during the packaging process.

-

Versatile capacity: Accommodates wire coils with a width ranging from 400 to 1000mm.

4. Online Steel Wire Coil Wrapping Machine

It

is an Online Coil Wrapping Machine and advanced packaging solution

designed for seamless integration into production lines. With its

built-in conveyor system, this machine effortlessly conveys wire coils

to the wrapping station, automatically positions them for accurate

wrapping, and ensures precise packing material counting and cutting. The

streamlined packing process results in increased productivity and

reduced labor costs.

Key Features:

-

Conveyor system: Enables efficient wire coil conveying and automatic positioning for accurate wrapping.

-

Automatic wrapping: Provides consistent and precise wrapping for a professional finish.

-

Packing material management: Ensures accurate counting and cutting of packing materials for optimal resource utilization.

-

Streamlined packing: Integrates seamlessly into existing production lines, enhancing overall efficiency.

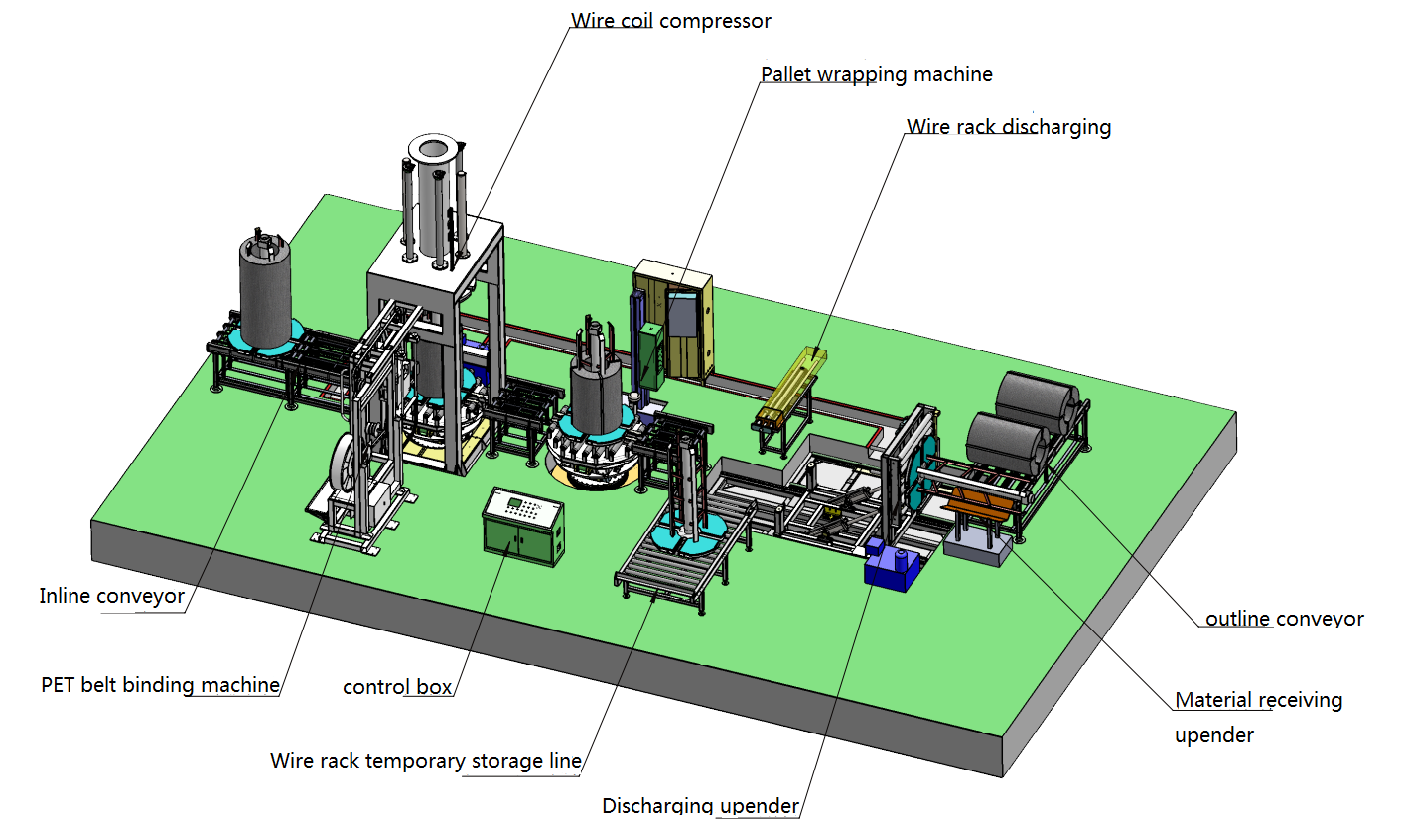

5. Automatic Wire Drawing & Packing Line

It

is Automatic rewinding packing systeme that is a revolutionary

packaging solution that streamlines the entire process of rewinding wire

from spools into smaller wire coils, followed by automatic strapping,

wrapping, and stacking. That is an invaluable investment for optimize

wire packaging processes while leveraging the benefits of advanced

automation, data tracking, and ERP system integration.

Key Features:

-

Comprehensive solution: Integrates wire rewinding, strapping, wrapping, and stacking in a seamless process.

-

New generation technology: Utilizes advanced automation techniques to optimize performance and efficiency.

-

ERP system integration: Seamlessly connects with existing ERP systems for improved inventory management and data tracking.

-

Data tracking: Monitors and records essential information for better decision-making and process optimization.

-

6. Automatic Wire Winding & Packing Machine

The machine designed for efficiently winds and packs wire coils. It integrates automatic wire feeding, winding, cutting, and packaging into a single system, ensuring precise coil formation, high-speed operation, and optimized packing for various wire types and sizes..

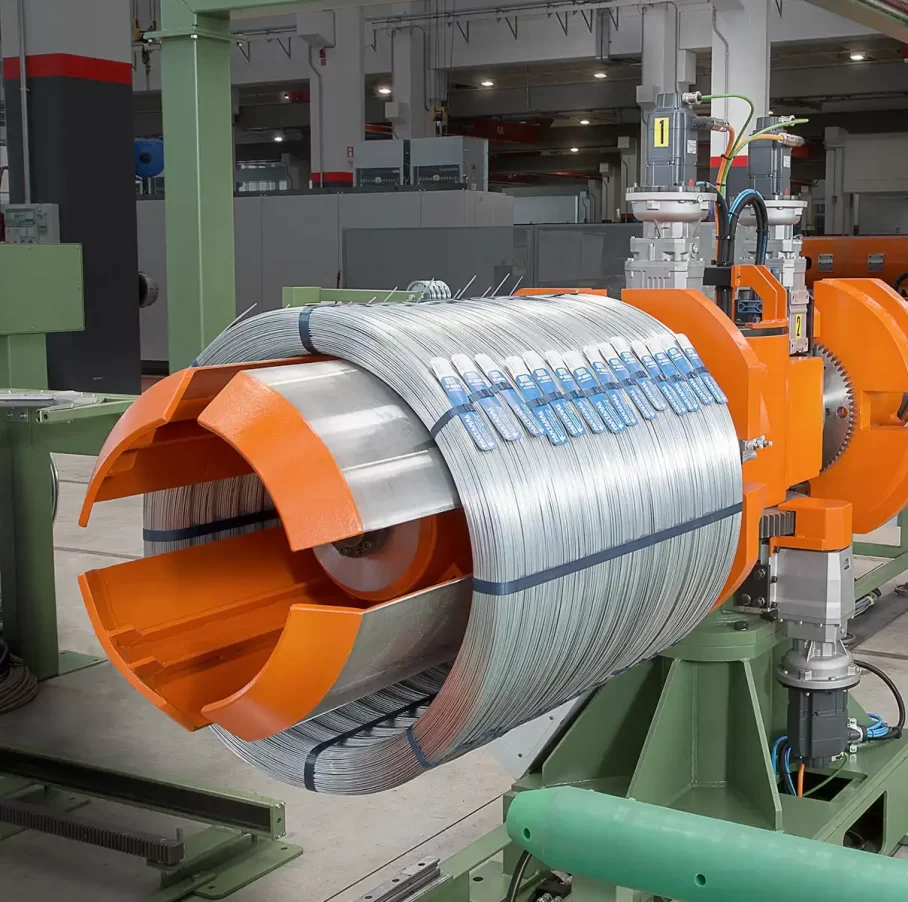

7. Automatic Wire Compacting & Packing Line

It

is an innovative packaging solution designed to optimize handling and

packing of wire with spools. This advanced system incorporates automatic

compacting and strapping, spool removal, and wire coil packing,

significantly reducing manual labor and forklift handling requirements.

Key Features:

-

Comprehensive solution: Streamlines steel wire compacting, strapping, spool removal, and coil packing processes.

-

Labor-saving: Replaces manual operations and forklift handling, enhancing efficiency and reducing labor costs.

-

Production integration: Connects seamlessly with wire drawing production lines for a fully automated workflow.

-

Enhanced safety: Minimizes risks associated with manual labor and forklift handling.

|

Wire coil packing machines are widely used in industries such as wire and cable manufacturing, steel and aluminum production, and other industries that require packaging of long and narrow items. The machines are essential for protecting the coils during transportation, storage, and handling, ensuring that they arrive at their destination in excellent condition. That is a valuable investment for any industry that relies on wire coils for their production process.

For the wire packing solution: There are semuauto wire

coil wrapping machine, wire winding machine wire coil re-winding and strapping machine... Also the automtion solution for the wire coil at the end of the prodcution line was volume production. The solution helps the user saving the labor cost and improving the packaging speed. Additionally labor- and time-saving attributes for instance Bluetooth technology, up-to-date wire coil pack machine and lines can be suited up with electronics that keep the track to move the production by part or weight, customer package count and weight, strapping preoccupied and a huge range of production and cost associated nitty-gritty.

Following tips are improtation in making the decision at the wire coil purchasing:

The coil handling way is important point that asking the wire packing machine matching to. For the light wire coil, it can be loading into packing station by rolling in&out manually, For the hevay load such as wire rod coil, PC wire coil, Pre-stress wire coil...that have to be handling by crane or forklifter. So selecting a packing solution that is easy to load the wire coil from top and enough space to avoid the compaction between the load and wrapping station. Conveyor both ok for light and heavy coils but price higher.

The machine works for different packaging material, but the packing material need to be confirmed before solution making. For different packaging goal, the following packing material will be choosing. Stretch film, paper, Kint belt, HDPE... It is able do one, two even three layers packaging at the same time.

It is no doubt that the most of automation wire packing solution is better than semiauto one without considering the price. Even choose the simplified solution, the compitibility and expansibility should be considered for further modification and solution upgarde.

Coil data and specifications are input manually into the machine's control system. This includes:

• Coil outer diameter

• Coil inner diameter

• Coil width

• Coil weight

• Required wrapping speed

• Number of wrapping layers

• Customer identification number

Download